— Konzernumsatz in Berichtswährung um 8,7 % auf 3.826 Mio. € gesteigert — Organisches Wachstum von 9,6 % erzielt

— EBITDA-Anstieg um 9,6 % auf 814 Mio. € — Anhaltend hohe Profitabilität mit einer EBITDA-Marge von 21,3 %

— Dividendenerhöhung von 0,97 € auf 1,02 € je Aktie vorgeschlagen

— Ausblick 2022: Umsatzwachstum von 5-7 % und EBITDA-Marge von um die 21 % angestrebt Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.symrise.com/de/newsroom/artikel/symrise-erzielt-im-jahr-2021-kraeftiges-umsatz-und-ertragswachstum-bei-hoher-profitabilitaet/

Evotec expands molecular patient database with unique nephrotic syndrome cohort from the university of Bristol

Evotec SE announced today that the Company has entered into a collaboration with the University of Bristol (“UoB”) to expand the Company’s molecular patient database in the field of kidney diseases with a focus on nephrotic syndrome. The nephrotic syndrome is a group of symptoms like proteinuria and oedema that indicate kidneys are not working properly. Diagnosis remains challenging and current treatment regimens are mostly symptomatic. Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.evotec.com/en/investor-relations/news/corporate-news/p/evotec-expands-molecular-patient-database-with-unique-nephrotic-syndrome-cohort-from-the-university-of-bristol-6147

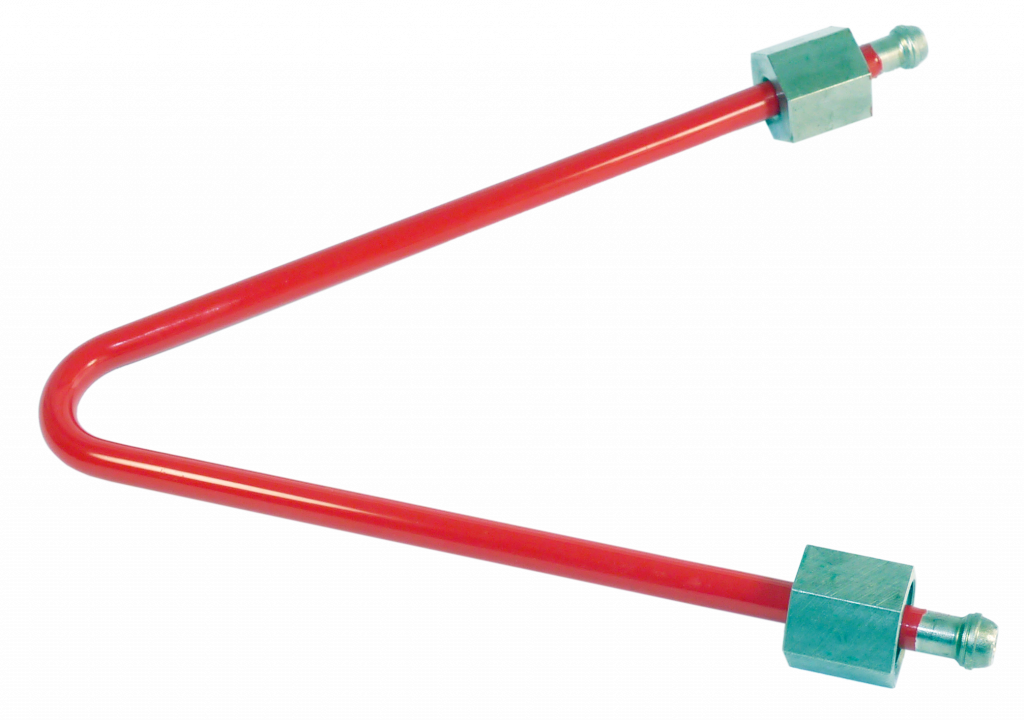

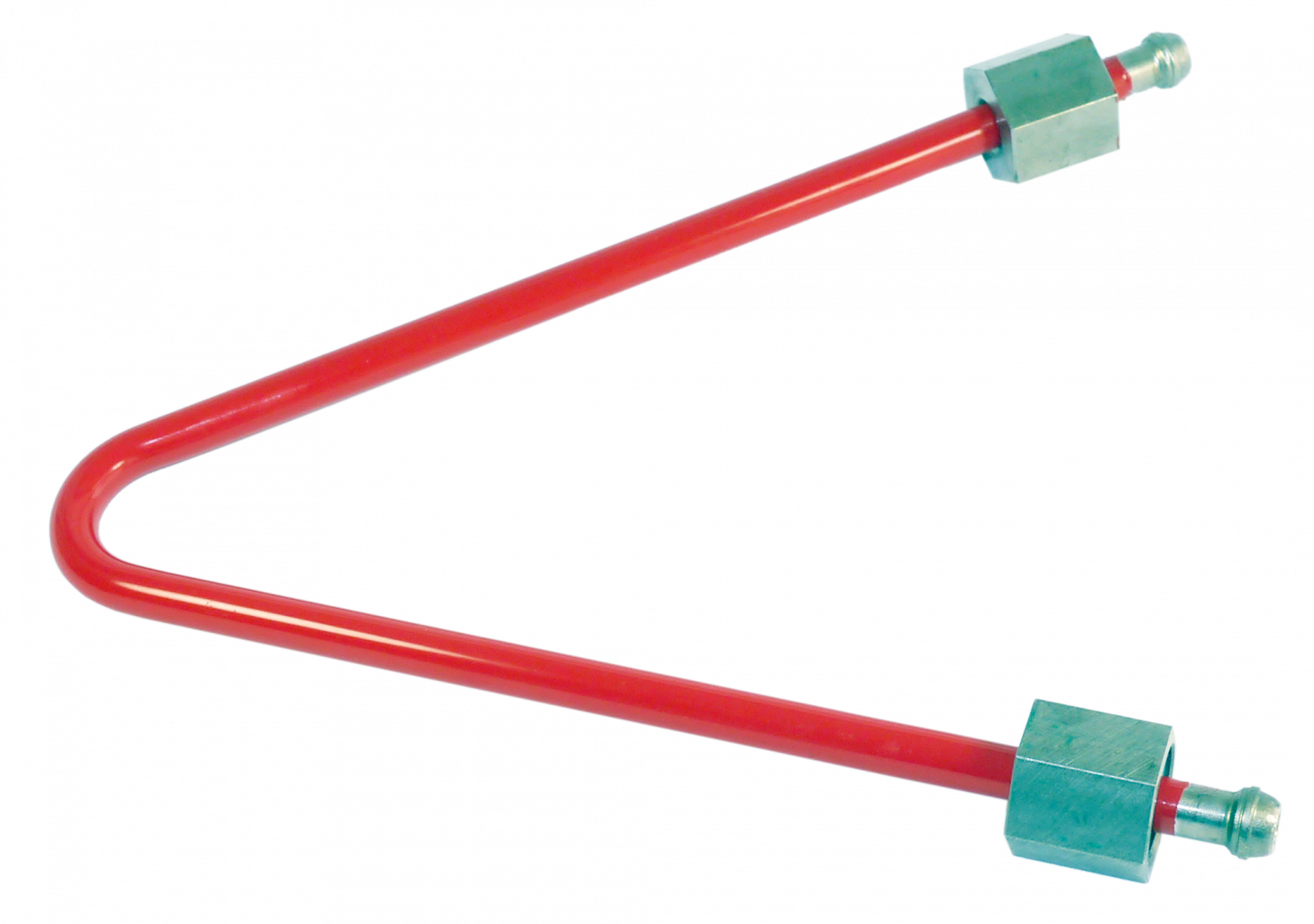

KBA erteilt EC 79-Zulassung für Wasserstoff-Hochdruckleitungen

Der Beitrag KBA erteilt EC 79-Zulassung für Wasserstoff-Hochdruckleitungen erschien zuerst auf Veritas AG.

Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.veritas.ag/kba-erteilt-ec-79-zulassung-fuer-wasserstoff-hochdruckleitungen/

Symrise baut Tiernahrungsaktivitäten in der Region Asien/Pazifik durch Übernahme von Wing Pet Food aus

— Wing Pet Food ist ein führender Hersteller von Geschmackslösungen mit Sitz in China

— Transaktion stärkt Marktposition von Symrise und beschleunigt Diversifizierung im Anwendungsbereich Heimtiernahrung

— Erweiterter Zugang zu Kunden in der Region Asien/Pazifik — Abschluss der Transaktion im zweiten Quartal 2022 erwartet Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.symrise.com/de/newsroom/artikel/symrise-baut-tiernahrungsaktivitaeten-in-der-region-asienpazifik-durch-uebernahme-von-wing-pet-food-a/

ProtiScan™ analysiert und charakterisiert Geschmacksstoffe in Pflanzenproteinen und deren Anwendungen

– Neuartiges Analyseverfahren zur Charakterisierung von alternativen Proteinen.

– Smarte Datenverarbeitung zur Charakterisierung der sensorischen Eigenschaften von Pflanzenproteinen.

– Forschungsgestützte Produktentwicklung von Lebensmitteln auf Basis alternativer Proteine. Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.symrise.com/de/newsroom/artikel/protiscanTM-analysiert-und-charakterisiert-geschmacksstoffe-in-pflanzenproteinen-und-deren-anwendunge/

Evotec participates in Centauri Therapeutics' Series A investment round

Evotec SE, together with Boehringer Ingelheim Venture Fund, and Novo Holdings REPAIR Impact Fund invested in Centauri Therapeutics Limited („Centauri“) GBP 24 m (c. US$ 32 m) Series A investment round. Founded by Animatrix Founders LLP, Centauri is an immunotherapy company focused on the treatment of infectious diseases. Additionally to the investment, Karen Lackey, Evotec’s Global Head of Integrated Drug Discovery will join Centauri’s Board of Directors. Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.evotec.com/en/investor-relations/news/corporate-news/p/evotec-participates-in-centauri-therapeutics-series-a-investment-round-6145

Evotec SE Invests In Data-Driven Biotechnology Company IMIDomics, Inc.

Evotec SE has made an equity investment in IMIDomics, Inc., a privately held global biotechnology company focused on the discovery and development of new targets and medicines for the treatment of patients with immune-mediated inflammatory diseases („IMIDs“). Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.evotec.com/en/investor-relations/news/corporate-news/p/evotec-se-invests-in-data-driven-biotechnology-company-imidomics-inc-6143

All Your Cell Counting Questions, Answered

… And Four Important Variables to Consider

– 8 min read

Cell counting can provide great insight into the state of your cell culture. Here, we answer all your burning questions on this topic, so get ready for the ride!

Key points:

- Quantifying cells helps you determine their viability and growth pattern

- Manual methods revolve around the use of hemocytometers observed through light microscopy

- Automated instruments are either based on electric impedance, flow cytometry or image cytometry

- Time-consumption, accuracy and consistency vary between these approaches

What is Cell Counting?

A simple yet important question. Some may say that cell counting is just counting cells. But in reality, it’s so much more than that. Among many things, cell counting is…

- …routine. Maintain consistency in experiments that involve cells by checking in on them. Making sure that they look and act as expected keeps you one step ahead.

- …insightful. It can tell you about cell viability as well as the standard deviation and variance if you perform the cell count multiple times. Of course, other factors than just the condition of the cells impact these numbers—more on this later.

- …caring. Caring for your cells and their health. Keep an eye on how they are doing in their culture medium and give them the best possible conditions to thrive.

- …being prepared. Plan and maintain a cell culture until it’s needed. It’s crucial to do this in different assays or protein production, for example, to ensure the desired results.

What Are The Methods?

The main distinction in the field of cell counting is made between manual and automated techniques. Both methods of counting cells require cell staining before being counted to differentiate between the dead and viable cells in a sample.

Especially in manual cell counting, trypan blue is often used to stain dead cells as it isn’t membrane permeable1. Other stains include propidium iodide (PI), erythrosine B, acridine orange (AO) and DAPI.

Let’s start by looking at manual method.

Manual Cell Counting

It’s a method that most of us are familiar with. You have a diluted cell culture (fx in PBS) which you stain. You can then count the cells using a hemocytometer and a tally counter2. For a more in-depth walkthrough, see our blog on hemocytometers.

Advantages: Most equipment only needs to be purchased once. The only interchangeable part is the hemocytometer, (which you can choose to wash and reuse), making it an extremely cheap way to count cells.

To fill one of the hemocytometer chambers you’ll only need 10 μl of diluted cell suspension, which allows you to do a count even if the volume of your cell culture is small.

Disadvantages: The method is prone to a lot of subjectivity regarding what defines a cell, and this can affect the accuracy of the total cell count. This problem is especially apparent when working with aggregated cells.

Also, you will need experience in handling a microscope to be able to count cells. It takes a relatively long time to count the cells manually and that also amounts to higher labor costs.

Let’s not forget the automated methods

Automated cell counters are divided into three types. It might seem a bit intimidating, but fear not—we’ll walk you through them.

Electrical Impedance-Based

Cell counters that are based on electrical impedance are also known as Coulter counters. These are based on the Coulter principle which states that the impedance of a particle in an electric current is different from that of its buffer or medium. The cells are counted by pumping them through an aperture and measuring the resistance 3.

Advantages: Coulter counters can count a lot of different types of particles including both nucleated and non-nucleated cells. Also, you get a true number of cells in each volume as opposed to the manual method where the cells/μl are estimated based on the cell count of a small area.

Disadvantages: This method doesn’t allow you to differentiate between viable and non-viable cells as opposed to image-based methods. Other limitations include: Small particles can go unnoticed, aggregates are counted as one cell and your choice of cell medium is limited to electrolytes.

Optical/Flow Cytometry-Based

Cells can also be counted and characterized by flow cytometry. Here, an excitation laser is directed towards the bypassing cells and the light scatter is passed through a variety of filters and detectors. These signals are then amplified and passed on to a computer system for analysis3.

Advantages: It’s a time-saving method that allows for fast and precise cell counting compared to manual cell counting. You can determine cell viability using this method by staining the cells with both a membrane-permeable and a membrane-impermeable fluorescent dye. The excitation wavelength of the viable cells will differ from the viable ones and reflect the cell viability.

Disadvantages: The essential tool here is a flow cytometer which is an expensive instrument compared to image-based cell counters (see the section below). Adding onto this cost, you will need training in using a flow cytometer to count cells. Difficulties can occur when quantifying cells that tend to clump.

Image-Based Cytometry

Image-based cytometry is highly dependent upon the image processing of cells, using machine learning and advanced algorithms tailored to the specific cell counting protocol.

These images are either taken through a brightfield or fluorescence microscope objective3.

Advantages: The computer-based cell recognition of this method allows for the quantification of aggregates.

It also ensures consistency regarding the cell counting protocol because the microscopy is handled by a computer to eliminate human bias.

Disadvantages: An image cytometer is a costly instrument compared to a hemocytometer. Many of these cell counters also require special one-time-use slides or cassettes for loading the sample.

Four Important Variables to Consider

Before committing to either manual or automated cell counting, here are some factors that you should consider:

#1 Price Matters!

A common standpoint is that manual cell counting is significantly cheaper because of the low cost of the hemocytometer as opposed to the cost of automated instruments. However, you need to take into consideration that it has the additional cost of human labor (which amounts to a LOT in fact).

It’s also prone to many errors2 and as we all know, errors are expensive. These expenses are eliminated when using an automated counter.

#2 Consistency is Key

Every scientist knows that for their experimental results to be valid, a researcher from another lab should be able to follow the same protocol and get the same results.

This reproducibility is ensured with automated cell counters because of the high degree of standardization as opposed to manual cell counting where other factors interfere with the results – more on this in section #3.

#3 Is the Human Eye Accurate Enough?

You’ve surely tried to carry out duplicate cell counts only to find that the numbers vary significantly from each other even though you used the same sample!

This problem is especially seen when manually counting cells, partly because of the human bias (which decides what is defined as a cell) and partly because a hemocytometer gets easily overfilled. You can avoid these issues with automated cell counters since human errors would be eliminated. Learn more.

#4 Fast-Tracking the Process

Initially automated cell counting can be time-consuming because it requires training, but once you get the hang of it, you will be speedier than with the manual method.

Manual cell counting is time-consuming because the cells are counted one by one and calculations like the total cell count and cell viability are done manually afterwards. With an automated method, all this work is handed over to the cell counter, freeing up time for all the other exciting projects in your lab!

Industries that Rely on Cell Counting

Now that you know (almost) everything about cell counting, we’d like to fill you in on what you can use it for.

- Cell therapy: Cell counting is used to determine the right doses for cell-based therapeutics as well as a tool to ensure that the product is standardized4.

- Bioprocessing: In this field, cell counting is used to routinely monitor the condition i.e. growth and viability of the cell cultures in the bioreactors. This allows for optimization of the output based on the cell culture’s growth phase5.

- Drug development: After cells have been treated with potential drug candidates, cell counting is used to monitor viability. It’s also crucial to ensure reproducibility6.

So, as you can see, the limits are endless. Whether it’s done manually or automated, cell counting has a lot of applications that will surely complement your lab work and help you obtain better results.

On that note, what are you waiting for? Go and try some of these different methods and find out which one is best suited for your lab. Happy counting!

Further reading

- Blog post: Manual cell counting 101

- Blog post: Spilling the Secrets: How to Count Cells with a Hemocytometer

- Mini-review: Manual vs. Automated Cell Counting

- Webinar: Are Sticky Cells Stickying up Your Data?

- Blog post: Is Trypan Blue Toxic? The Dark Side of the Popular Stain

- Webinar: Is PBS affecting your cells?

- The NucleoCounter® range: Automated Cell Counters & Analyzers

References

- Johnson, S., Nguyen, V. and Coder, D. (2013), Assessment of Cell Viability. Current Protocols in Cytometry, 64: 9.2.1-9.2.26

- Electron Microscopy Sciences: Neubauer Haemocytometry

- Vembadi A, Menachery A, Qasaimeh MA. Cell Cytometry: Review and Perspective on Biotechnological Advances. Front Bioeng Biotechnol. 2019;7:147

- Sarkar S, Pierce L, Lin-Gibson S, Lund S (2019). Standards Landscape in Cell Counting: Implications for Cell & Gene Therapy. Cell and Gene Therapy Insights. 5. 117-131. 10.18609/cgti.2019.016.

- Butler M, Spearman M, Braasch K (2014). Monitoring Cell Growth, Viability, and Apoptosis. Methods in molecular biology (Clifton, N.J.). 1104. 169-92. 10.1007/978-1-62703-733-4_12.

- Niepel M, Hafner M, Mills CE et al. A Multi-center Study on the Reproducibility of Drug-Response Assays in Mammalian Cell Lines. Cell Syst. 2019 Jul 24;9(1):35-48.e5

By Christina Psaradaki, Student Assistant at ChemoMetec

Christina Psaradaki studies Human Life Science Engineering at the Technical University of Denmark. At ChemoMetec, she writes for the Cell Counting Blog.

Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://chemometec.com/cell-counting-questions-answered/

Ad hoc: Evotec SE – Bayer discontinues clinical development candidate eliapixant (BAY1817080); Evotec regains the rights to all P2X3 assets

Evotec SE announces today that the Company has been informed by Bayer about a decision to discontinue the development of the investigational P2X3 receptor antagonist eliapixant (BAY1817080), which stems from a former Evotec/Bayer multi-target research alliance. Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.evotec.com/en/investor-relations/news/ad-hoc-releases/p/ad-hoc-evotec-se—bayer-discontinues-clinical-development-candidate-eliapixant-bay1817080-evotec-regains-the-rights-to-all-p2x3-assets-6141

Evotec expands sustainability at Dorothy Crowfoot Hodgkin Campus

Evotec SE announced today that the Company plans to significantly invest in its site at Milton Park, named Dorothy Crowfoot Hodgkin Campus, to reduce the CO2 emissions. The project will help to achieve the company’s carbon neutral targets. Die Original-Meldung zu diesem Chemie Unternehmen finden Sie unter https://www.evotec.com/en/investor-relations/news/corporate-news/p/evotec-expands-sustainability-at-dorothy-crowfoot-hodgkin-campus-6140